Introduction to Steel Utility Poles

Richard F. Aichinger, PE,

and

John C. Huang, Ph.D., PE,

Course Outline

This course introduces steel utility poles to engineers in the utility industry. It provides the detailed information on current design standards, load and strength factors, and the performance of the steel utility poles. This course includes a multiple-choice quiz at the end, which is designed to enhance the understanding of course materials.

Learning

Objectives

At

the conclusion of this course, the student will:

Course Content

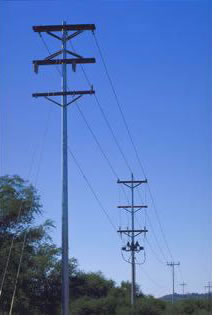

Because of the material characteristics, steel utility poles are stronger, more

durable, and environmentally friendlier than their wood counterparts. In addition

to being recyclable, another one of the environmental advantages of steel distribution

poles is that they are resistant to insects and rot. Therefore, unlike traditional

wood poles, steel poles do not need toxic chemical preservative treatments and

do not create future hazardous waste disposal concerns.

Because of the material characteristics, steel utility poles are stronger, more

durable, and environmentally friendlier than their wood counterparts. In addition

to being recyclable, another one of the environmental advantages of steel distribution

poles is that they are resistant to insects and rot. Therefore, unlike traditional

wood poles, steel poles do not need toxic chemical preservative treatments and

do not create future hazardous waste disposal concerns.

Steel utility poles are fabricated with uniform dimensions from ASTM tolerance

materials - providing superior strength, consistent performance, and enhanced

reliability. Steel poles also have the flexibility to be designed as direct

wood pole replacements, or can be engineered to meet any specific loading criteria.

To prevent corrosion, steel distribution poles can be galvanized or coated.

They are lighter in weight and easier to install, require less maintenance,

and offer lower overall life cycle cost.

When a steel pole is designed as direct wood pole replacement, two main factors govern the selection of a wood "equivalent" steel pole. They are the length of the poles and the groundline moment capacity. ANSI 05.1 "American National Standard for Wood Poles - Specifications and Dimensions" dictates the minimum moment capacity for each pole:

The "Equivalent Steel Pole" loading is determined by multiplying the horizontal load required by ANSI 05.1 (for each wood pole class) by the ratio of National Electrical Safety Code (NESC) defined overload factors for wood and steel poles.

Wind loads normally have the greatest impact on the design of the utility poles. Other loads affecting the design of the utility poles include cable/wire self-weight and possible ice load.

Steel poles shall also be designed so their stresses meet ASCE Manual 72 "Design of Steel Transmission Pole Structures" allowables for bending and local buckling over the entire length of the pole (not just at the groundline).

The

advantage of steel poles is structural designs meeting minimum stresses defined

by ASTM Standards rather than mean stress values as used by wood. This assures

that steel poles achieve the required equivalent load capacity every time, with

consistent dimensions and predictable performance. Once

you finish viewing the slide shows and studying the FAQ,

you need to

take a quiz

to obtain the PDH credits.

In this lesson, you need to

Quiz

***

Additional Technical Resource and Further Readings:

The current National

Electric Safety Code (NESC, 1997 edition) contains an apparent disprepancy in

steel and wood pole safety factors. This disprepancy is expected to be corrected

in the 2002 edition of NESC.

If

you need a copy of 1997

National Electrical Safety Code or ASCE

Manual 72 - Design of Steel Transmission Pole Structures (Second Edition,

1990), you may visit www.UtilityBookstore.com.

For

additional information on steel utility poles, please visit the websites of

the following

steel pole manufacturers:

Thomas & Betts Corporation *** Acknowledgment:

PDHonline.org acknowledges the sponsorship of

American Iron and Steel Institute (AISI)

for this online course.

***

Valmont Industries, Inc.

Once you finish viewing the slide shows and studying the FAQ, you need to take a quiz to obtain the PDH credits.

![]()

DISCLAIMER:

The materials contained in the online course are not intended as a representation

or warranty on the part of PDH Center or any other person/organization named

herein. The materials are for general information only. They are not a substitute

for competent professional advice. Application of this information to a specific

project should be reviewed by a registered professional engineer. Anyone making

use of the information set forth herein does so at their own risk and assumes

any and all resulting liability arising therefrom.

![]()