Calculate Factor of Safety Against Thread Stripping

with A36 body

When a bolt is fully engaged into a nut or when a screw

has a depth of engagement at least equal to the diameter

of the screw, the thread engagement is adequae. Special

situations arise when the bolt is not fully engaged

into the nut or when the screw is engaged into a much

weaker material. Sufficient design margin against

failure by thread stripping should be provided.

The determination of the required pre-load is outside

the scope of this paper since it is dependent on the

function of the joint, for eg. gasket seating, joint

sealing, etc. A minimum residual pre-load stress of

20% of yield strength of the bolt is recommended by

Ref. 8 for torque retention. Otherwise, torque retention

devices such as lock nuts, jam nuts, lock washers,

staking of threads, locking adhesives, etc would be

required.

If this is an ASTM A193, Gr. B7 bolt, it would not have

reached the plastic range since the von Mises stress

is much less than the yield strength of the bolt (105

ksi).

Von Mises stress is given by combining tensile stress

with shear stress as follows:

However, Code Interpretation III-1-91-15 states that

Section NB-3232 does not apply to this situation. Thus,

we could instead use Von Mises stress for combining

tensile stress with shear and check against yield for

ASME or non-ASME components

For an ASTM A93, Gr. B7 bolt, the allowable stress intensity

would be 3 Sm,

i.e. 3 x 35 ksi =105 ksi and has not been exceeded.

The shear stress is the highest at the periphery of

the bolt cross-section which is also subject to an

axial tensile stress. For ASME components, the rules

of NB-3232.2 could be used to determine the maximum

allowable stress. This requires calculating the stress

intensity which is defined as twice the maximum shear

stress or the difference between the principal stresses.

Thus,

Note

: The full applied torque is not experienced by the

cross-section of the bolt since some of this torque

goes to overcome friction under the nut head.

The shear stress is the thread torque divided by the

polar section modulus.

Allowable Tensile Stess:

There is no clear guidance for the maximum allowable

average tensile stress for preload. For ASME components,

ASME III NB-3230 could be used. Provided differential

thermal expansion does not create additional stresses,

the maximum allowable average tensile stress could

be considered as 2 x Sm

since internal pressure would not increase the bolt

loading. For ASTM A193 B7 at a service temperature

of 200 deg. it would be 2 x 32.6 ksi and about 60%

of yield.

References:

1. Fastener Standards, 6th Edition, Industrial Fasteners

Institute, 1988

2. AISC Manual of Steel Construction, 8th Edition, 1980

3.

Mechanical Engineering Design, J.E. Slingley & L.D.

Mitchell, McGraw-Hill

4.

An Introduction to the Design and Behavior of Bolted

Joints, by John H. Bickford

5. ASME Boiler & Pressure Vessel Code, Section III,

19?? Edition

6.

Development of Design Charts for Bolts Preloaded up

to the Plastic Range, N. Motosh,

Journal of Engineering for Industry, ASME Aug.

76

7.

Fastener Design Manual, Richard T. Barrett, NASA Reference

Publication 1228, 1990

8. Bolted Joint Maintenance and Applications Guide,

TR-104213, EPRI, December 1995

9. Specification for Structural Joints Using ASTM A325

or A490 Bolts, AISC, 1978

The author wishes to thank Dr. Yinyao Jiang, Dr. Peter

Turula, and Bill Eccles for helping the author understand

some technical points presented in this paper.

The required preload per Table 3 is 12000 lbs. Therefore,

the rotation for 2400 lbs would be:

The bolt in this example has a preload of 2400 lbs.

According to Table 4, the nut rotation for 1/2"

A325 bolt would be 1/3 turn or 120 degrees for a bolt

less than 4 diameters in length.

However, an approximate amount of nut rotation can be

calculated based on Tables 3 and 4 of Reference 9.

Although it is theoretically possible to calculate the

nut rotation as a function of the preload, it does

not correlate well with observations for preloads less

than yield. If tightening to preloads beyond yield

strength is permissible, this is a cost effective and

reliable method and is widely used for structural connections

installing A325 or A490 bolts.

Calculation of Nut Rotation

Note: External threads used and methodology in Reference

1.

Using methodology in Reference 7.

for Carbon Steel; for Stainless Steel use 0.55

(Use the material property for the weaker material)

2a

is the angle of the thread and is 60 degrees for UNC

thread

this is the distance between nut flats for hex nuts

dm

is the effective contact diameter for the threads and

is the average of major and minor diameters; It is

also approximately equal to the pitch diameter.

TPI is threads per inch.

l is lead.

dc

is the effective contact diameter between the nut and

joint surface and is the average of major diameter

and the distance between parallel nut flats for a hex

nut.

Determine Torque vs. Tension Relationship

for 1/2" bolt with hex nut as the turning element

Set the parameter, i, according to the size of the bolt.

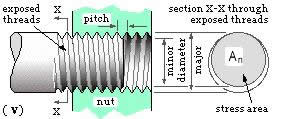

The following table gives bolt geometry and thread engagement

data for UNC bolts from 1/4" diameter to 1 1/4"

diameter. First row gives the major diamter, second

row gives the minor diamter, third row gives the number

of threads per inch, and the fourth row gives the distance

between nut flats for hex nuts (1/4" to 5/8"

sizes), and heavy hex nuts (3/4" to 1 1/4"

sizes). The last two rows give the thread stripping

areas per inch for external and internal threads respectively.

This information is obtained from References 1 &

2.

Definitions:

Sm is the design stress intensity for the bolt material per ASME B &

PV Code.

The major diameter is the largest

diameter of a screw thread. It is also the nominal size of the bolt.

The minor diameter is the smallest

diameter of a screw thread. Also referred to as root diameter.

The lead is the distance the nut

moves parallel to the screw axis when the nut is given one turn. For a single

start thread used in bolts, screws, nuts, etc., the lead is the same as

the pitch and is the inverse of number

of threads per inch.

The pitch diameter is the diameter

of an imaginary coaxial cylinder cutting the threads at a height where the

width of the thread and groove are equal. The average of major and minor

diameters is approximately equal to the pitch diameter.

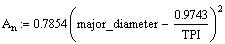

The stress area is the effective

cross-sectional area of the bolt that resists bolt fracture.

The thread angle is the included

angle between the flanks of a screw thread.

Calculate Tension in bolt when subject to a known torque

Calcualte max stress in bolt when subject to a pre-load

and determine its acceptability

Calculate factor of safety against stripping failure

for a known thread engagement

Determine whether a torque retention device is required

Calculate nut rotation for a given bolt torque

Introduction:

During maintenance activities in a power plant environment,

the plant engineer is often called upon to make decisions

concerning bolts in bolted connections in a variety

of situations. Most of these bolts are torqued to

achieve a pre-load rather than being tensioned with

a tensioner. Examples include: increasing bolt torque

beyond vendor manual recommended values to stop leaks,

vendor recomendations for torquing are not available,

bolt holes need to be enlarged to install replacement

components, bolts may require trimming to accomodate

replacement component, lack of thread engagement, etc.

The ability to perform a component level analysis

on a bolt, will provide the plant engineer an engineering

tool to make the correct technical decision.

Progress Energy, Southport,

NC 28461

Analysis of Bolt Torquing

ds is the diameter

based on stress

area.

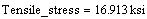

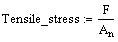

Tensile stress will be calculated using the stress area:

We can either use the results of the long or short formula

for the value of F for this analyis.

Calculate maximum stress on the bolt during the torquing

process:

This short formula gives results which compares well

with the results of the long formula. However, it

is important for the Nut factor to be selected carefully,

since it significantly affects the results.

Nut factors are determined empirically. For values

of Nut factor for various lubricated fasteners See

Reference 4.

for unlubricated NEW steel fasteners

There is a simple empirical formula ("short formula")

that is widely used in the industry to calculate the

relationship between Torque and Tension. It is given

by:

Suppose we apply a torque of 20 ft.lb.(240 in.lbs)

Further, it should be noted that only the torques represented

by the first two terms will create a twist in the body

of the bolt.

From this expression, it can be seen that bolt and thread

geometry and the ceofficient

of friction significantly influence the relationship

between torque and

preload. If the above expressions are evaluated it will

be seen that only about 10% of the applied torque works

to achieve the preload and the remainder works to overcome

friction.

This expression can be mathematically simplified as

such that

the first term represents the amount of torque to stretch

the bolt and compress the joint

the second term represents the amount of torque required

to overcome the friction between the nut and bolt threads

the third term represents the amount of torque required

to overcome the friction on the face of nut when multiplied

by the preload F.

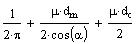

See Reference 3; "long formula"

Given an applied torque, T, the preload force F in the

bolt is given by

T= F x

Factor where:

m

is the coefficient of friction assuming non-lubricated

steel bolt and is assumed to the same for friction

between threads and between nut and joint surface.

A more realistic coefficient of friction for fasteners

that has been in service may by 0.35-0.40 rather than

0.15.